BME (Basics of Mechanical Engineering) lab is a very essential lab to understand the basic fundamental concepts, construction, working principle of various mechanical systems equipped with working or cut sections models like clutch, brake, Internal Combustion Engines, Steam Boilers etc.

The objective of Heat Transfer Lab is to establish and perform experiments related to three different modes of heat transfer: 1. Conduction 2. Convection 3. Radiation. It includes the phase change process like boiling and condensation. It also covers the study of heat exchangers.

Mechanical Engineering Workshop is a place of where students acquire knowledge on the operation of various process involved in manufacturing and production. The workshop practice course makes students competent in handling practical work in engineering environment.

Refrigeration and Air-conditioning Laboratory (RAC Lab), with an aim to train students in the broad field of refrigeration and air-conditioning through studies involving refrigeration cycles, psychometric processes, and relevant system/sub-system design and performance characterization.

The purpose of Fluid Mechanics and Hydraulic Machinery laboratory is to reinforce and enhance understanding of the fundamentals of Fluid mechanics and Hydraulic machines. It can be studied when fluid at rest and fluid in motion.

The lab is a dedicated lab for the automotive electronics components of automobiles. Working of carburetor, supercharger and turbocharger, working of differential, starting system, various components of internal combustion engine, and steering systems are some of the equipment in the lab used for demonstration and experimentation.

The CAD (Computer-Aided Design) lab provides a digitally integrated environment to develop skill to use software to create 2D and 3D models, students can design, analyze, simulate, generate CNC codes, and build models. With the help of CAD software available in the lab, students can present their ideas into drawings in the form of 2D/3D models and can explore new possibilities in the engineering design.

The key objective of MMM lab is to provide a platform to the students for the learning of internationally accepted standards, measuring instruments, calibration techniques, GD&T, and drawing reading , focuses on the analysis of various metal properties, structure, heat treatment process, failure detection, etc.

This lab contains equipment and models through which the students are able to synergize theory and practical skills. The important areas of dynamics are balancing, vibrations, whirling, and other basic principles of applied mechanics which are fully covered using this range of products.

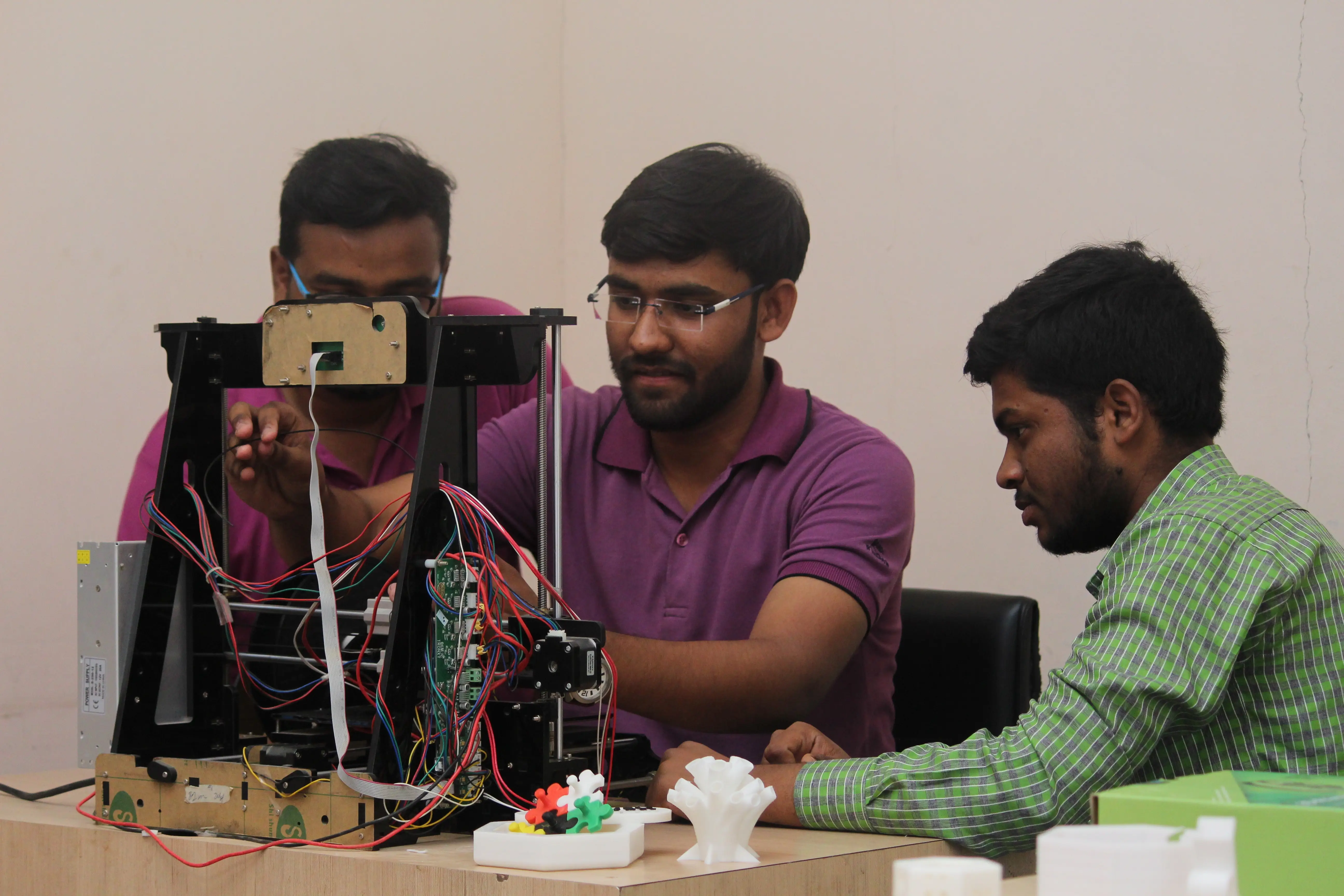

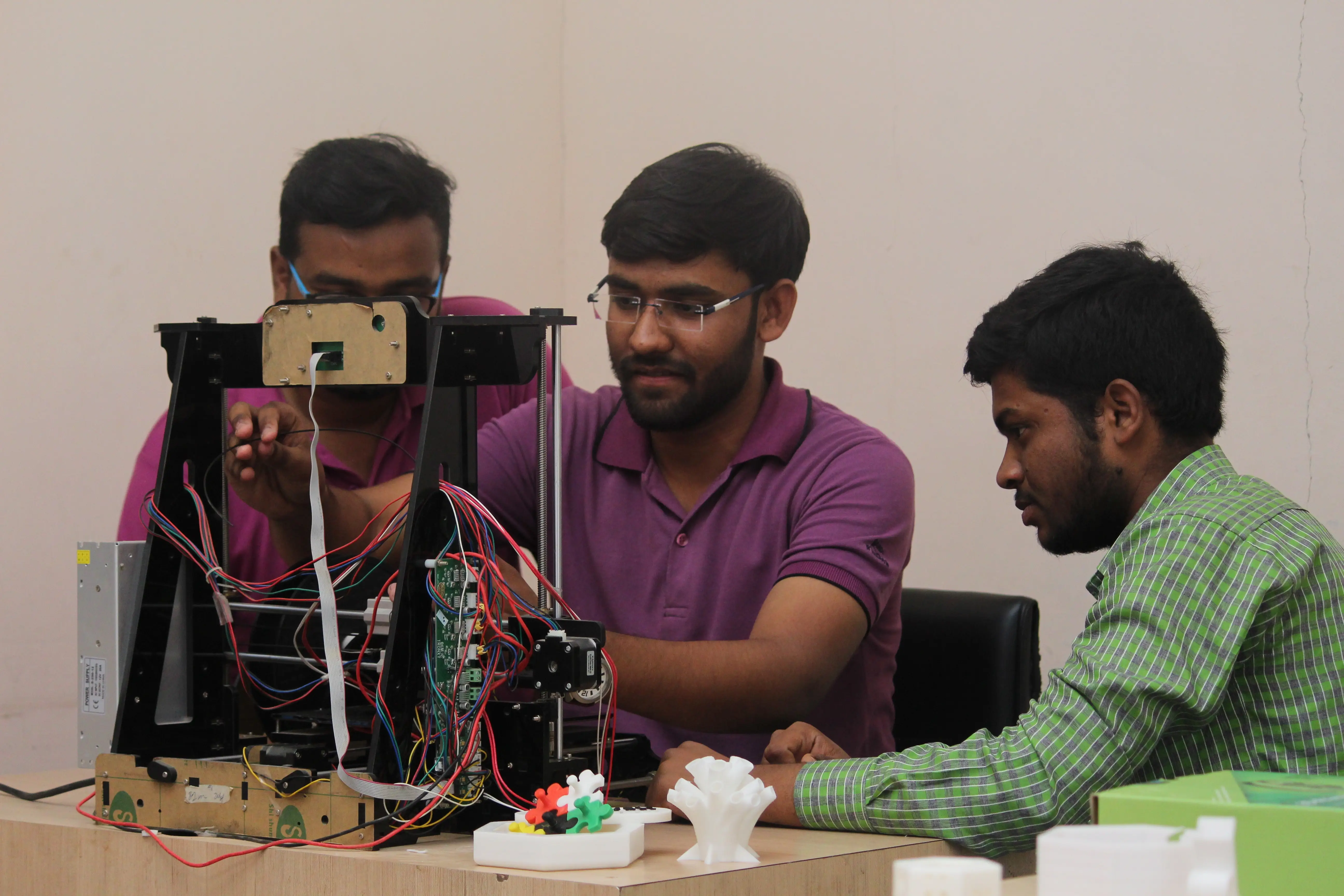

Rapid prototyping is the fast fabrication of a physical part, model or assembly using 3D computer aided design (CAD). The creation of the part, model or assembly is usually completed using additive manufacturing, or more commonly known as 3D printing.

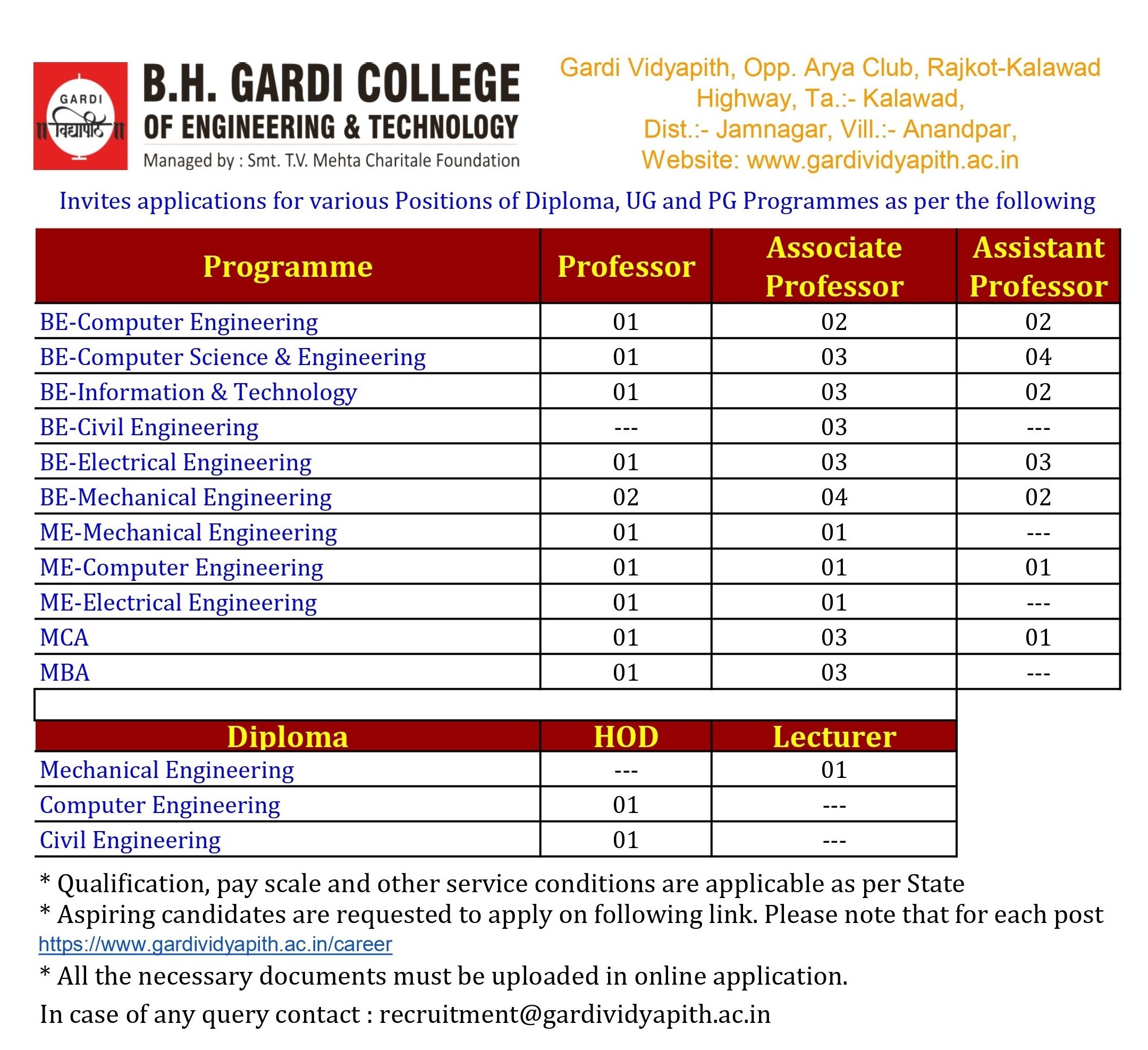

Faculty Recruitment

Enquire Now

Alumni Meet 2025

Faculty Recruitment

Enquire Now

Alumni Meet 2025